Maintenance Key Performance

Indicators

Performance measurement is a fundamental principle of management. The measurement of performance is important because it identifies current performance gaps between current and desired performance and provides indication of progress towards closing the gaps. Carefully selected key performance indicators identify precisely where to take action to improve performance.

Purpose - Using this indicators will enhance the mindset of faster learning, enabling a culture of looking forward to improving performance instead of looking back to pinpoint failures.it is used to

Maintenance Key Performance Indicator

Daily/Weekly/Monthly Plan Examples and calculate the Maintenance KPIs to achieve best result

Schedule Compliance - Weekly distribution of work according to available resources

(Material,Man Power) and Work Priority.It measures the percentage of performed scheduled

operations vs. the total estimated scheduled operations

PM % = Preventive Maintenance % - Execution of Preventive maintenance work based on

Weekly Planning

Breakdown % = Any Breakdown attended during the Week.

Emergency / Unscheduled Work% = Any Emergency work execution during the week which

may urgent to prevent Major break down or safety/environment related major issues.

Weekly Pending Hrs = Work could not executed due to Emergency work or breakdown

maintenance or unavailability of equipment. Work planned and scheduled but not done

Overtime% = Any Major breakdown during the Week or delayed with respect to Weekly

schedule or lack of Planning

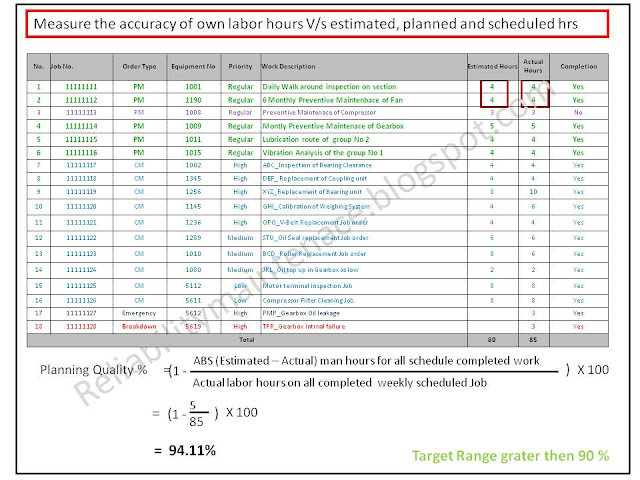

The planning Quality KPI measures how close the planned hours on the job order to the actual

hours required to complete the job order in the weekly plan. The objective is to measure how

close the planned estimate and schedule the hours needed to complete the job.

Record the reason of deviation in order to take into account the actual data for future planning

of the same work.

Outstanding hour means all resources available including material manpower.

Performance measurement is a fundamental principle of management. The measurement of performance is important because it identifies current performance gaps between current and desired performance and provides indication of progress towards closing the gaps. Carefully selected key performance indicators identify precisely where to take action to improve performance.

Purpose - Using this indicators will enhance the mindset of faster learning, enabling a culture of looking forward to improving performance instead of looking back to pinpoint failures.it is used to

- Implementing preventive maintenance strategy

- Improve work planning

- Labor utilization by better scheduling

- Usage of data history

Maintenance Key Performance Indicator

Daily/Weekly/Monthly Plan Examples and calculate the Maintenance KPIs to achieve best result

Schedule Compliance - Weekly distribution of work according to available resources

(Material,Man Power) and Work Priority.It measures the percentage of performed scheduled

operations vs. the total estimated scheduled operations

PM % = Preventive Maintenance % - Execution of Preventive maintenance work based on

Weekly Planning

Breakdown % = Any Breakdown attended during the Week.

may urgent to prevent Major break down or safety/environment related major issues.

Weekly Pending Hrs = Work could not executed due to Emergency work or breakdown

maintenance or unavailability of equipment. Work planned and scheduled but not done

Overtime% = Any Major breakdown during the Week or delayed with respect to Weekly

schedule or lack of Planning

The planning Quality KPI measures how close the planned hours on the job order to the actual

hours required to complete the job order in the weekly plan. The objective is to measure how

close the planned estimate and schedule the hours needed to complete the job.

Record the reason of deviation in order to take into account the actual data for future planning

of the same work.

It is emergency work That creates overtime and as a serious safety issues due to the lack of planning.

Outstanding hour means all resources available including material manpower.

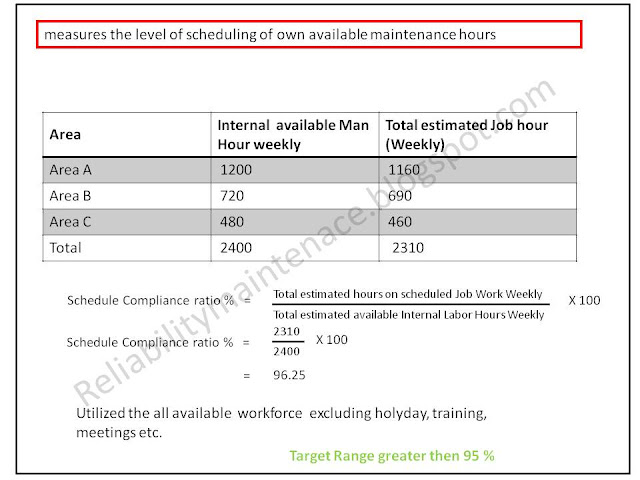

Weekly Schedule compliance - It is used to utilized all available hours excluding holiday ,internal

or external training, meeting etc.

ConversionConversion EmoticonEmoticon